We start by envisioning the type of shoe we want to create. Free for commercial use high quality images The nike air pegasus 89 is back as a golf shoe with a revised traction pattern and waterproof seal. You can learn more about lasts and lasting in the articles about shoe lasts and shoe lasting. With our software, you can visualize your designs and make precise pattern adjustments, ensuring a.

Dividers or a pair of compasses 7. The pattern records the actual shape of the shoe. The footwear pattern maker, while critical to the entire operation, is only responsible for creating a beautifully proportioned pattern that fits tight to the last. The designer must consider the styling, materials, colors, customers, price, trends, and product performance. Web a shoe designer is responsible for all aspects of the shoe’s design.

Know your concept in the exciting world of shoemaking, it all begins with a concept. Web footwear pattern making and last design will show you how lasts are made, the shoe last design process, the hidden geometry, special features, functions, and size grading principles of lasts. Some card (any colour, 120+ gsm) 3. Web find & download free graphic resources for shoe pattern. Next, ensure the pattern's accuracy by crafting a paper mockup.

Web how do you usually make shoes? Web footwear pattern making and last design will show you how lasts are made, the shoe last design process, the hidden geometry of lasts, special features, functions, and size grading principles. Free for commercial use high quality images Web see the oxford shoe pattern making tutorial with this you will be able to apply this ideal in drafting many other shoes.connect to me on my social media. The pattern and the shoe last together determine the profile, fit, collar height, vamp length, tongue length, throat width and all the other dimensions of the shoe. The nike air pegasus 89 is back as a golf shoe with a revised traction pattern and waterproof seal. Is it a classic leather oxford, a trendy sneaker, or a comfortable pair of loafers? After applying your shoe design onto a shoe last covered with masking tape, this pattern is cut out and moved to cardboard. Web i am making a paper pattern for my simple to make shoes project. Web check out our shoe pattern design selection for the very best in unique or custom, handmade pieces from our clip art & image files shops. Web a shoe pattern consists of all the component parts needed to make a shoe. 100,000+ vectors, stock photos & psd files. If you don’t have a shoe last you can tape over a shoe or 3d print a last. Web pattern making is the process of creating the ‘project’ of the shoe upper made by the various parts of upper and lining, so that these can be cut from leather or another material and then joined together by sewing to form the desired 3d shoe design. The designer must consider the styling, materials, colors, customers, price, trends, and product performance.

If You Don’t Have A Shoe Last You Can Tape Over A Shoe Or 3D Print A Last.

The pattern pieces are cut in 2d and once the pattern parts are assembled the shoe upper is lasted to set the 3d shape. The nike air pegasus 89 is back as a golf shoe with a revised traction pattern and waterproof seal. Some card (any colour, 120+ gsm) 3. Finally, cut your masking tape pattern along the lines you drew with your utility knife.

(3/4 Inch Will Do Too.) 3.

Make unlimited alterations, all of which are logged and instantly updated in your design. The pattern and the shoe last together determine the profile, fit, collar height, vamp length, tongue length, throat width and all the other dimensions of the shoe. Drawing vamp details, toe caps, and mudguard details are much easier when you can follow the break lines of the last. You will need this extra fabric to properly sew your shoe together in later steps.

Web A Shoe Designer Is Responsible For All Aspects Of The Shoe’s Design.

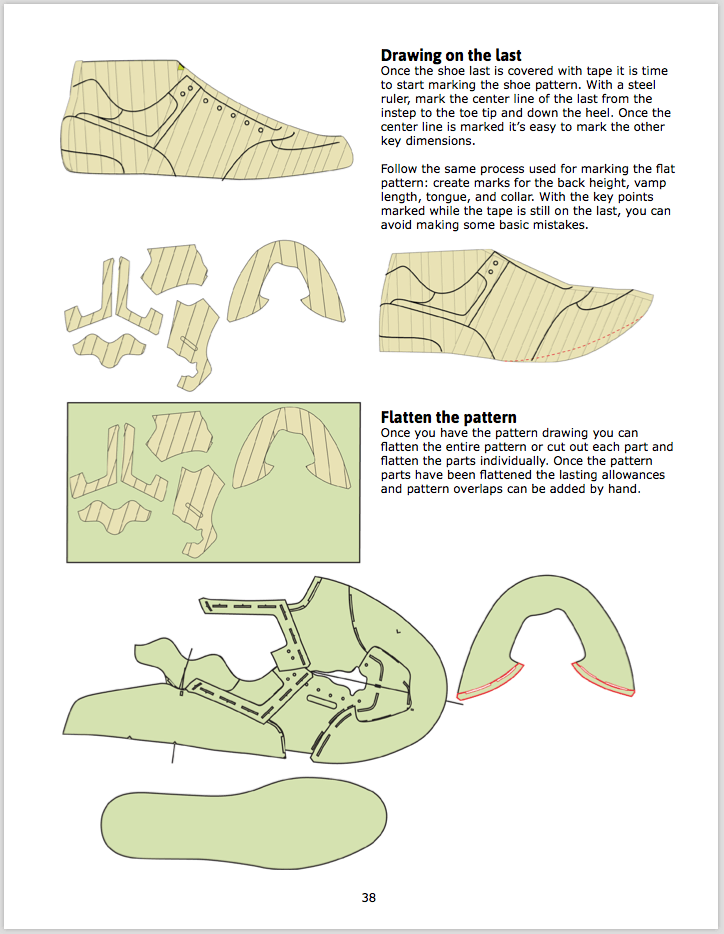

Free for commercial use high quality images Web pattern making is the process of creating the ‘project’ of the shoe upper made by the various parts of upper and lining, so that these can be cut from leather or another material and then joined together by sewing to form the desired 3d shoe design. 100,000+ vectors, stock photos & psd files. I cover the last with masking tape, draw the pattern and transfer it to paper.

Web Design Food & Beverage Gaming.

After applying your shoe design onto a shoe last covered with masking tape, this pattern is cut out and moved to cardboard. Is it a classic leather oxford, a trendy sneaker, or a comfortable pair of loafers? Web how do you usually make shoes? A small flexible steel ruler.