These patterns significantly impact the final. If you have a fillet weld. These patterns can include the. You use this motion to make cover welds over stringer beads. As the name implies, you set up the mig welder in the place it needs to be and then hold it steady.

You will make a weaving pattern in order to cover a larger area. You will make a weaving pattern in order to cover a larger area. Web by using different weave patterns, welders can control the amount of heat and penetration, ensuring the weld is strong and secure. These patterns significantly impact the final. This technique is most commonly.

As the name implies, you set up the mig welder in the place it needs to be and then hold it steady. You will make a weaving pattern in order to cover a larger area. Web a weave bead uses a crisscross motion to move the weld puddle and lay the bead, which is useful for vertical welding processes where avoiding drips is essential. Weave pattern beads are beneficial when you’ve got a broader joint to weld, as they will result in a nice wide bead. Web alternative patterns for mig welding holding still.

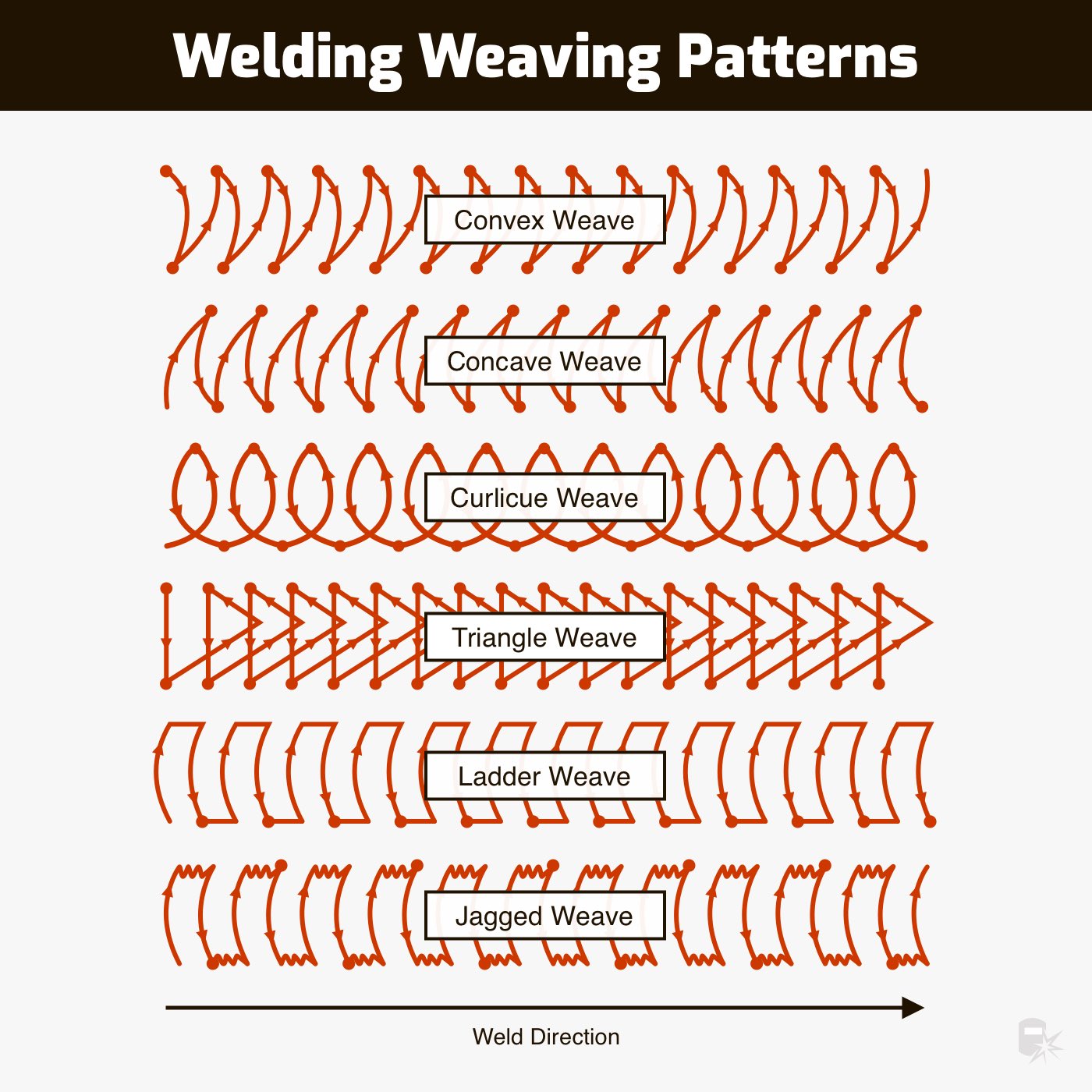

You will make a weaving pattern in order to cover a larger area. Web weave bead welding involves making a weaving pattern in order to cover a larger surface area. Thus, the welder can use many different patterns to spread the filler. Web the four easiest mig welding patterns for beginners to learn and master are the steady motion pattern, the whipping pattern, the circle pattern, and the weave. Web some common weave patterns include: Web by using different weave patterns, welders can control the amount of heat and penetration, ensuring the weld is strong and secure. Web vertical welding is one of the four basic welding positions where the joint’s axis is vertical to the ground, at an angle ranging from 45° to 90°. These patterns can include the. Walking the cup and freehand. For example, you can use the. As the name implies, you set up the mig welder in the place it needs to be and then hold it steady. These patterns significantly impact the final. If you have a fillet weld. The weaving technique is about more than just moving up and down. We’ll hit on the latter in a bit, but right now let’s focus on the former.

Web Some Common Weave Patterns Include:

Thus, the welder can use many different patterns to spread the filler. You use this motion to make cover welds over stringer beads. Web the weaving technique is a pattern welding technique that involves a side to side motion in creating the foundation of the pattern. Web moreover, these beads are much narrower than others.

Should I Stick Weld Downhill Or.

You will make a weaving pattern in order to cover a larger area. This motion allows you to make cover welds over stringer beads,. These patterns significantly impact the final. For example, you can use the.

Web Most Used Stick Welding Patterns.

Weave pattern beads are beneficial when you’ve got a broader joint to weld, as they will result in a nice wide bead. Walking the cup and freehand. Web vertical welding is one of the four basic welding positions where the joint’s axis is vertical to the ground, at an angle ranging from 45° to 90°. Web weave bead welding is exactly as it sounds;

Web A Weave Bead Uses A Crisscross Motion To Move The Weld Puddle And Lay The Bead, Which Is Useful For Vertical Welding Processes Where Avoiding Drips Is Essential.

Web 25k views 2 years ago. Web vertical 7018 welding can benefit from using a weave type pattern. This technique is most commonly. As the name implies, you set up the mig welder in the place it needs to be and then hold it steady.